U.S.A. Imagine buying a newspaper for a few dollars that not only showed you news stories, but also displayed videos, newsfeeds and live broadcasts. Imagine having clothes with solar panels sewn into them to charge your phone, or having clear windows that harvest energy from the sunlight. This might seem like something out of a sci-fi movie, but through new advancements in plastic electronics this could be possible in the near future.

Current computers are using silicon as their backbone and semiconductor of choice. However, plastic-based electronics are taking over the silicon market in three main areas. These are namely cheap, large-scale, but low-power electronics; large-scale solar power; and displays such as televisions and phones.

Silicon must go through many manufacturing steps until it is ready to be made into processors, which makes the process expensive and not easily scalable. This becomes a problem when creating large solar panels and making many processors. Current displays are large, thick and brittle because they use glass as their substrate. All of these problems can be solved with plastic electronics using conductive organic molecules.

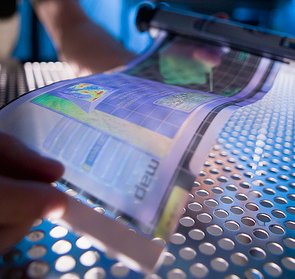

Flexible Display | Wikimedia Commons

Recently researchers at Stanford have demonstrated printing large sheets of organic field effect transistors (OFETs) onto sheets of plastic. This is especially difficult as plastic cannot withstand the high temperatures necessary to do this on silicon. They have shown that it is possible to “inkjet print” transistors and connections onto large sheets of plastic, similar to the way newspapers are printed. This means that small computers could be mass produced and made at low costs as parts of plastic displays or solar cells.

Last year, Samsung gave a preview of some flexible displays for phones that could appear on its next generation of smartphones. Sony recently released a 13-inch digital paper display for reading books and PDFs. Sony also released a flexible display that can be rolled around a pencil, like a scroll. These displays can be placed in odd locations, or fitted to anything. For example, a display could be stitched into a glove or steering wheel.

The biggest hurdle to having solar power become a primary power source is that is is cost relative to other forms of power. Although current plastic-based solar cells have only 5% efficiency, compared to the 14% to 17% of other solar cells, the efficiency is slowly increasing. Researchers at Northwestern University have created solar cells that reach a similar fill factor to silicon cells, with up to 8–9% efficiency. Although they are not as efficient as silicon and glass solar cells, they are much stronger and more flexible, allowing them to be put in different environments.

What makes plastic electronics so much more difficult to work with is the different chemistry and design involved in the organic molecules. Instead of electrons being excited from the ground state to a free state, like in silicon, electrons are excited from ground state to an excited state. This means that instead of having a free electron to make electricity, another molecule has to pick up the excited electron and move it to another conductor where it can create electricity. This makes the design of these plastic electronics very complicated, and is a major hurdle in the design of one of these systems.

Although plastic electronics may never achieve the same efficiency or power as silicon electronics, they have a special place as cheap, scalable, disposable electronics. They can be used very effectively as a silicon replacement when flexibility is a key component. Although the future may not be in plastic, it serves as a viable alternative to silicon.